본문 영역

Sponge Blast

An introduction to the basic concept of Sponge Blast.

-

01Sponge Blast is a representative method of low dust and eco-friendly blast, and it is a surface treatment method that drastically reduces dust and waste generated during Sand Blast.

-

02Sponge Blast uses a material that encapsulates abrasives (Aluminum Oxide, Garnet, etc.) in a specially formulated porous sponge particle called Sponge Media.

-

03Sponge Blast uses compressed air to blast Sponge Media to remove rust, paint and contaminants from the substrate to create surface roughness and surface cleanliness that meet the required specifications.

Main Characteristics

Discover the key benefits of Sponge Blast at a glance.

-

Low dust

The blasted Sponge Media absorbs dust through its compression and expansion upon impact with the substrate, reducing airborne dust generation by up to 98% compared to conventional Sand Blast. -

Reusable

After collecting the used Sponge Media, the recycler equipment is used to sort and classify reusable Sponge Media and foreign substances. The sorted Sponge Media can be reused up to 10 times. -

Improved Safety

Low dust blast method ensures worker visibility, reduces the repulsion of Sponge Media to ensure worker safety and protects surrounding equipment/facilities from dust.

-

Eco-friendly

- Scattering dust generation is reduced by up to 98% compared to Sand Blast, thereby minimizing the spread of air and surrounding pollution.

- Waste generation is reduced by 94% compared to Sand Blast.

-

Applicable to various fields and purposes

- The type and particle size of abrasive used in the Sponge Media can be selected according to the application field and purpose of use.

- It can achieve a surface roughness of 0–125 µm

- It also ensures surface cleanliness up to Sa 3 / SP5

Application Area

Introducing various industrial applications of Sponge Blast.

-

Shipbuilding/Marine

Shipbuilding/MarineSurface treatment and painting repair work before painting ships.

-

Construction/Civil Engineering

Construction/Civil EngineeringSurface treatment of bridges, steel structures, and concrete.

-

Plant/Industrial Equipment

Plant/Industrial EquipmentInternal surface treatment of tanks, pipes, and pressure vessels.

-

Military/Aviation Industry

Military/Aviation IndustrySurface maintenance of aircraft fuselage and military equipment.

-

Cultural Heritage Conservation

Cultural Heritage ConservationSurface treatment of stone, statues, and building exteriors.

Sponge Blast Concept

We introduce the principles, components, and technical advantages of Sponge Blast.

-

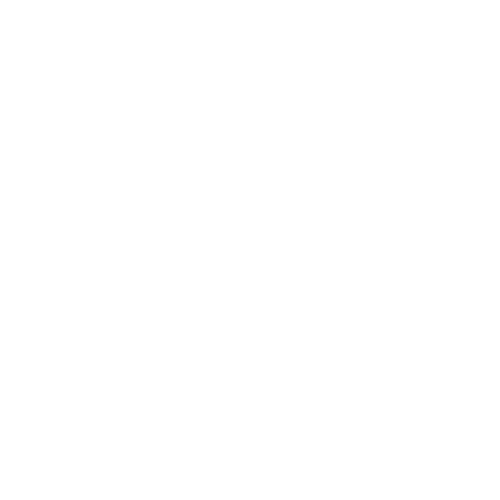

01Blasting

- Sponge Media encapsulated with abrasives (Aluminum Oxide, Garnet, etc.) in specially formulated porous sponge particles are blasted using compressed air.

-

02Removal of contaminants and creation of surface roughness on the substrate surface

- When the Sponge Media impacts the surface, it momentarily flattens, exposing the abrasives inside.

- The exposed abrasives remove rust, paint, and contaminants from the surface, creating the desired surface roughness and cleanliness.

-

03Dust Absorption

- The compressed Sponge Media expands, it absorbs the dust generated during blasting into its porous structure.

-

04Collection and Reuse

- After collecting the used Sponge Media, it is processed through a dedicated recycler that separates reusable Sponge Media from contaminants. The sorted Sponge Media can be reused up to 10 times.

Sponge Media Recycle

We introduce the principles, components, and technical advantages of Sponge Media Recycle.

-

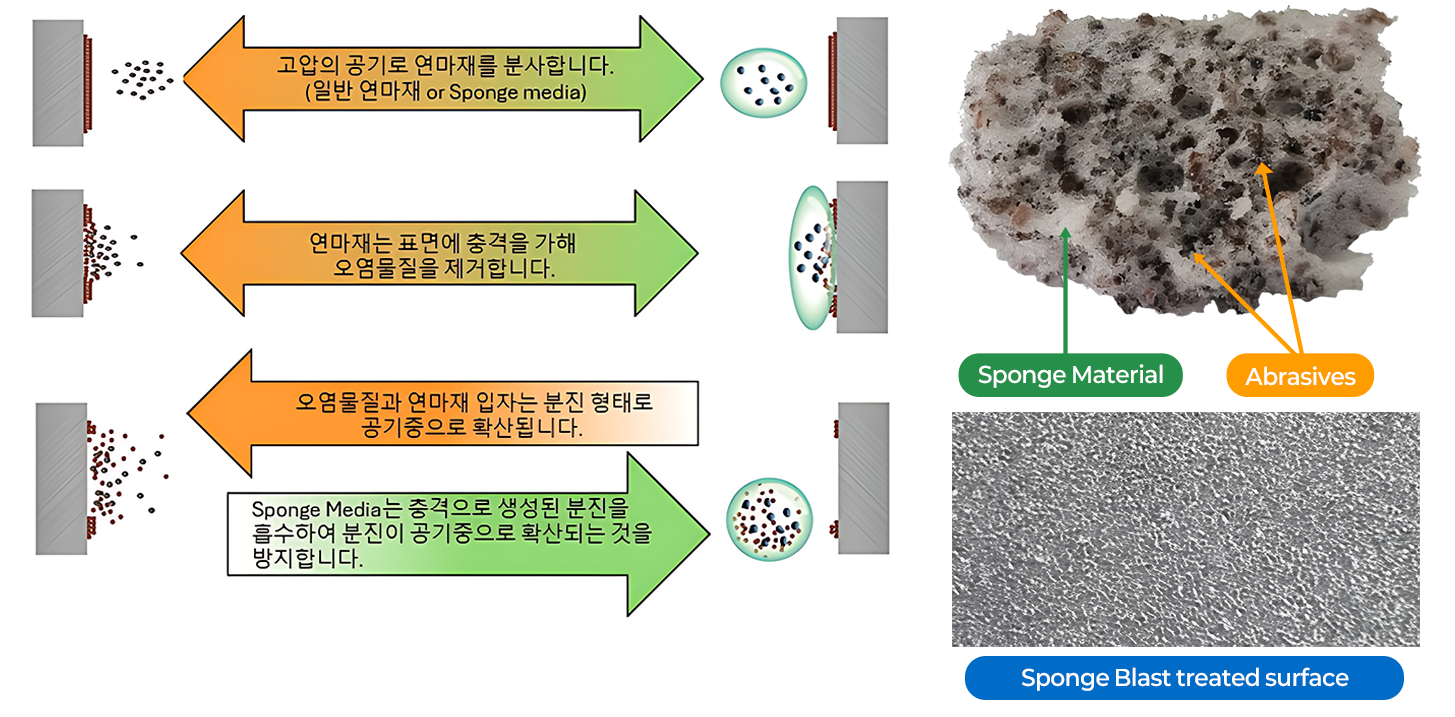

01Blasting

- Sponge Media is projected with compressed air to impact the substrate surface and remove contaminants.

-

02Collection

- The used Sponge Media is collected after blasting.

- The collected Sponge Media is a mixture of abrasives and contaminants such as rust, removed paint, and dust.

-

03Separation

- Use the dedicated recycler separates reusable Sponge Media from contaminants.

-

04Reuse

- The sorted Sponge Media is fed back into the blasting equipment and can be reused up to 10 times.

Sponge Blast Advantages

Discover the key benefits of Sponge Blast at a glance.

-

Excellent surface treatment

Excellent surface treatment- It can ensure surface cleanliness up to Sa 3 / SP5.

- It also achieve a surface roughness of 0–125 µm.

-

Low dust

Low dust- Reduces dust generation by up to 98% compared to Sand Blast.

- It can work safely in limited environments such as enclosed spaces.

- Protects nearby sensitive equipment from dust during Blasting.

- Improves operator visibility, reducing rework and enhancing safety.

-

Reusability

Reusability- Sponge Media can be reused up to 10 times.

- Reduces waste by up to 94% compared to Sand Blast.

- Lowers costs for abrasive handling, transportation, and waste disposal.

-

Reduced Dwon-time

Reduced Dwon-time- Low dust generation allows simultaneous operation with other work activities, Prevents cost loss due to work stoppages.

-

Improved Salt Removal Efficiency

Improved Salt Removal Efficiency- Improved surface chloride removal - 60% improvement in chloride removal efficiency compared to Sand Blast.

provides a safer working environment by improving worker visibility, and allows the reuse of abrasive(Sponge Media).

As the surface treatment industry seeks more eco-friendly and safer alternatives, Sponge Blast, with its advantages of excellent surface preparation,

low dust generation, environmental friendliness, reusability, and improved working conditions, sets a new standard for surface treatment technology.

본문 영역